It is common to use traditional 3D printing materials like plastic. However, there are a number of uncommon material possibilities that can make the 3D-printed object even more unique as well. We introduce you to these uncommon materials in our list. You can now create astonishing and strange objects out of anything, from chocolate to salt to recycled plastic garbage or ash. In some instances, these materials even show to be a great replacement for plastic, lowering overconsumption and its associated environmental impact.

Materials for 3D printing from the ocean

Today, filaments are still the most widely used materials for 3D printing, largely due to the accessibility of FDM machines. However, did you know that some filaments are already produced using crabs and shellfish? Materials created from PLA and shells from mussels, scallops, and oysters are available. These shells are crushed and turned into filaments using recycled food service trash. The materials can be printed like regular PLA!

Salt obtained locally

American company Emerging Objects produces amazing projects by combining modern technologies with cutting-edge materials. One of the most remarkable projects is Saltygloo, a building created by 3D printing salt. Locally, salt from San Francisco Bay was used. Due to the local climate, some 500,000 tons of sea salt are generated here each year. Large-scale additive manufacturing of lightweight structures was done with the salt.

The sweetest 3D printing material is chocolate.

Even while this 3D printing substance may not be as spectacular as some of the others on the list, it is undoubtedly one of the most popular. Although the chocolate 3D printing technique is similar to FDM technology, it takes longer since chocolate cools more slowly than plastic. As this technology has grown in acceptance over time, numerous businesses have created numerous initiatives, including chocolate 3D printers.

Filaments made of wood

Additionally, plant- or wood-based filaments have been on the market for a while. The PLA/PHA base is often combined with the wood fibers to provide products a natural, high-quality finish. The filaments can be applied anywhere a wooden appearance is desired, whether they are being used to create figurines, furniture, or wall decorations. But it is advised to slow down the printing process when using this filament to prevent issues.

3D glass printing

Glass has been widely utilized for a long time in a variety of industries, including additive manufacturing. Several researchers have created 3D printing strategies to make glass printable, such as those from MIT or Lawrence Livermore National Laboratory (LLNL). For instance, the G3DP2 device, created by the MIT team, can process 5 kg of glass each hour. At Milan Design Week, the researchers used this machine to construct 3-meter-tall glass columns.

Created from discarded plastic filaments

Many enterprises are searching for alternatives as the issue of sustainability in the field of additive manufacturing becomes more and more important. A number of intriguing items have been created in recent years with the goal of making 3D printing more environmentally friendly by creating filament from recycled plastic. One such project is Print The City by The New Raw, where benches and other street furniture are printed using 3D printing filament made from plastic garbage from inhabitants of Amsterdam and Thessaloniki. The Million Waves Project is an additional project that intends to generate filament from recycled PET to 3D print prosthetic limbs for individuals who are in need.

An ivory-inspired material for 3D printing

Some of the many materials used for 3D printing have been specially created to fulfill particular needs and creatively address long-standing issues. Digory is one such material that was created by the University of Vienna in partnership with Cubicure GmbH to address the demand for restoring historical structures and ivory-based artifacts. It is a synthetic resin made of silicon oxide powder and calcium phosphate particles. In order to recreate things using 3D printing or SLA technology, researchers have created a new material with qualities and capabilities similar to those of ivory. There is almost any difference between the two materials, which is astonishing similarity.

A more sustainable 3D printing material is clay.

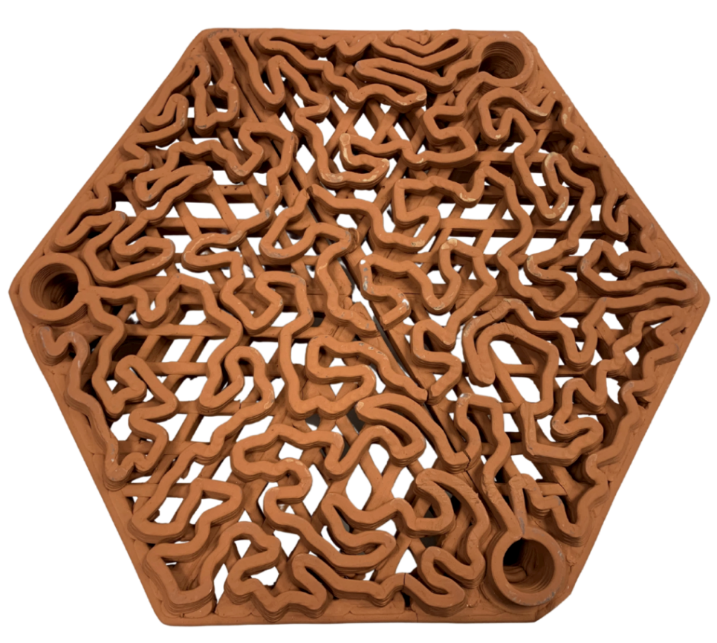

Clay is a unique 3D printing material that has undoubtedly gained attention in recent years. Technically a branch of ceramic 3D printing, which is notorious for its amazing capabilities despite being challenging to print with, the usage of clay in particular has gained popularity thanks to the efforts of the Italian firm WASP. For instance, WASP and Honda are employing clay 3D printing to produce more environmentally friendly automobiles. There are numerous additional uses as well, although many of them focus on sustainability because of the characteristics of clay. This is demonstrated by initiatives like the use of 3D printed clay containers for food waste reduction or the use of terracotta tiles by archiREEF to rehabilitate coral in Hong Kong.

Clay is a unique 3D printing material that has undoubtedly gained attention in recent years. Technically a branch of ceramic 3D printing, which is notorious for its amazing capabilities despite being challenging to print with, the usage of clay in particular has gained popularity thanks to the efforts of the Italian firm WASP. For instance, WASP and Honda are employing clay 3D printing to produce more environmentally friendly automobiles. There are numerous additional uses as well, although many of them focus on sustainability because of the characteristics of clay. This is demonstrated by initiatives like the use of 3D printed clay containers for food waste reduction or the use of terracotta tiles by archiREEF to rehabilitate coral in Hong Kong.